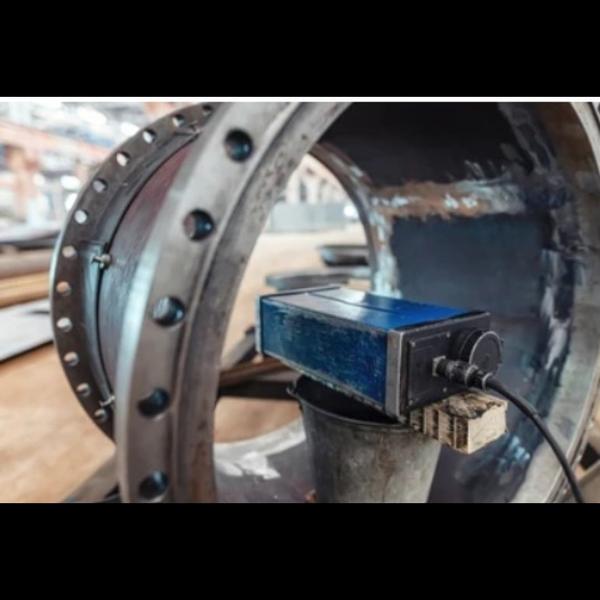

Radiography Testing Radiographic Testing (FT) is a non destructive examination (NDE) technique that involves the use of either x-rays or gamma rays to view the internal structure of a component. During Radiographic Testing, the test-part is placed between the radiation source and film (or detector). The material density and thickness differences of the test-part will attenuate (i.e. reduce) the penetrating radiation through interaction processes involving scattering and/or absorption. The differences in absorption are then recorded on film(s) or through an electronic means. In industrial radiography there are several imaging methods available, techniques to display the final image, i.e. Film Radiography, Real Time Radiography (RTR), Computed Tomography (CT), Digital Radiography (DR), and Computed Radiography (CR). We Have Extensive Range Of Equipment Of Low and High Energy To Maintain Quality Requirement of Our Esteemed Customer As Follows:- X-RAY Machines For Thickness Range of 1MM TO 30 MM Se 75 Sources For Thickness Range of 4 MM TO 30 MM Ir 192 Sources For Thickness Range of 20 MM TO 70 MM Co 60 Sources For Thickness Range of 60 MM TO 200 MM Castings : Sand And Investment Casting Of Thickness 04 Mm To 200 Mm From All Industrial Sector Including Aerospace and DRDO. Welding : Boiler Tubes, Pressure Vessel and Tanks Applications: Aerospace industries Military defence Offshore industries Marine industries Power-gen industries Petrochem industries

Godavari Technical Services

About Godavari Technical Services

The Best Non-Destructive Testing (NDT) and Industrial Inspection Services in nashik

Services

Featured ServicesWhat We Do

Have any custom requirements?

9+

HAPPY CLIENTS

Latest Updates

Read Our Latest Updates & News

×

![]()